Description

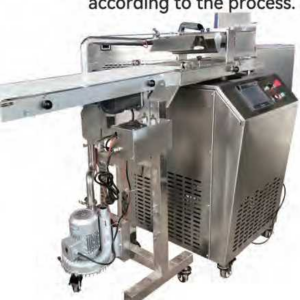

Chocolate melting and holding tank with pump has a wide range of application in the chocolate production and pastry shop. You can use it to store large amounts of chocolate to maintain continuous production. In addition, it can also be used as the auxiliary equipment of injection molding machines and automatic temperature control machines and other equipment, to make up for their problem of low storage.

Technical Specification

Capacity: 250L

Forced water cooling

Scraped surface stirrer

Pulsed water inlet control for maximum efficiency

Typically uses 50% less water than competitive tanks

Good access for cleaning

Constructed from high quality stanless steel

Enclosed insulation

Digital, programmable controller

Plumbing needed (infeed/outfeed)

Dimension: 892mm(L)x791mm(W)x1560mm(H)

Power: 4.5kw

Water needed:70L

Tags: chocolate melter machine

How can a chocolate melter machine achieve rapid melting of chocolate blocks or pieces to meet the needs of chocolate making and coating?

Chocolate melter machine achieves rapid melting of chocolate blocks or pieces by using controlled heat and agitation. It maintains a precise temperature range, gently melting the chocolate without overheating it. This controlled process ensures the chocolate is in its ideal state for molding, dipping, or coating applications, meeting the requirements of chocolate making and production.

What capacity options are typically available for this type of equipment to accommodate chocolate production of different scales and capacity requirements?

It is important to note that the capacity options for equipment used in chocolate production can vary depending on a number of factors, such as the type of equipment, the production process, and the specific manufacturer.

1. Small scale – For small-scale chocolate production, equipment may have a capacity of up to 20-30kg per batch or hour.

2. Medium scale – For medium-scale production, the capacity of equipment can range from 50kg to 500kg per hour.

3. Large scale – For large-scale production, equipment can have a capacity of over 500kg per hour.

4. Semi-continuous – Some equipment may offer a semi-continuous production process, which falls between batch and continuous production.

5. Continuous – For continuous production, equipment can have a capacity of over 1000kg per hour. These machines are designed for high-speed and large-scale production, making them suitable for large chocolate factories or industrial-sized chocolate production.

What are the performance characteristics of a chocolate melting machine in maintaining the ideal working temperature of chocolate to ensure its quality and fluidity?

Chocolate melting machine is designed to maintain the ideal working temperature of chocolate, and its performance characteristics include precise temperature control and even heating. By keeping the chocolate within a specified temperature range, typically around 31-32°C (88-90°F) for dark chocolate and slightly lower for milk and white chocolate, it ensures that the chocolate remains in a liquid state without overheating or burning. This level of control preserves the chocolate’s quality, texture, and fluidity, making it perfect for molding, coating, or other chocolate-related applications in a consistent and reliable manner.

What control and safety functions are commonly used in chocolate melter machines, so that operators can use them safely and conveniently?

1. Temperature control: Chocolate melters have a temperature control system that allows operators to set and maintain the desired temperature for melting chocolate.

2. Auto shut-off: In case of an emergency or if the temperature of the chocolate exceeds the set limit, a safety feature like an auto shut-off function is activated to prevent accidents.

3. Overheat protection: Overheating of chocolate can lead to fires and other hazards.

4. Digital display: A digital display on the control panel of a chocolate melter allows operators to accurately monitor and adjust the temperature.

5. Timer: A timer function allows operators to set a specific time for the chocolate to melt, after which the machine will automatically shut off.

6. Thermostat: A thermostat is a safety device that constantly monitors the temperature of the chocolate and shuts off the machine if it reaches a dangerous level.

7. Easy-to-clean design: A chocolate melter with an easy-to-clean design ensures that operators can maintain a clean and safe working environment without the risk of contamination or accidents caused by leftover chocolate.