What is wafer stick machine?

A wafer stick machine is a specialized equipment used to manufacture wafer sticks, also known as cigar rolls or rolled wafers. These crunchy and hollow tubes of wafer are often filled with various cream and chocolate flavors, making them a popular snack choice worldwide. The process of making wafer sticks involves combining ingredients, baking thin sheets of batter, cutting and shaping them into cylinders, and filling them with desired fillings. In this article, we will dive into the details of how a wafer stick machine works and its various features.

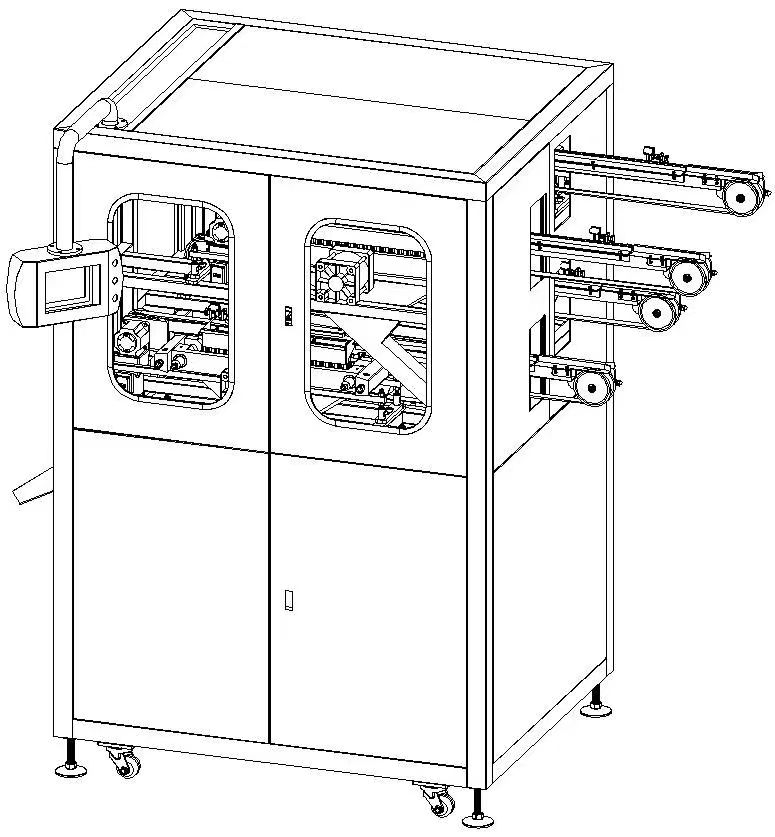

How does it work?

The first step in making wafer sticks is the preparation of the batter. A wafer stick machine usually consists of a mixing tank where the batter ingredients are combined. The ingredients include wheat flour, starch, eggs, sugar, and oil. The mixing tank ensures that all the ingredients are well blended before the batter is pumped into a holding tank.

Once the batter is ready, it is then fed through a nozzle into a series of baking plates. These plates are heated at a controlled temperature to bake thin sheets of wafer batter. The plates are designed with a specific texture and pattern to give the wafer sticks their distinct design. The baking process typically takes about 2-3 minutes to produce a continuous sheet of wafer batter.

As the wafer sheets exit the baking plates, they are then cut into the desired shape and size by a cutting machine. The cutting machine ensures that the wafer sheets are cut evenly and without any distortion. The cut wafer sheets then move on to the next stage, where they are rolled and molded into cylindrical shapes.

The wafer rolling and molding machine consist of a cone-shaped mold and a rolling pin. The rolled wafer stick is then transferred to a cooling conveyor belt, where it is quickly cooled to maintain its shape. Once the wafer sticks have cooled, they are then transferred to a filling machine, where they are filled with various flavors of cream and chocolate.

The filling process is a crucial step in the making of wafer sticks and requires precision and accuracy. The filling machine usually consists of a nozzle, which injects the filling into the wafer stick. This can be done either through a single nozzle, which fills the wafer sticks one at a time, or a multi-nozzle machine, which can fill multiple sticks at once.

After the filling process, the wafer sticks are then sealed with a sealing machine, ensuring that the filling stays intact inside the hollow wafer tube. The sealed wafer sticks then move on to the packaging stage, where they are packed in various sizes and shapes, ready for distribution.

One of the significant advantages of using a wafer stick machine is its efficiency in producing a large number of wafer sticks in a short amount of time. These machines are ideal for mass production, making them popular among wafer stick manufacturers. The machines are also designed to be highly versatile, allowing for different shapes, sizes, and flavors to be produced with minimal adjustments.

Another essential feature of wafer stick machines is their flexibility. This means that they can be easily integrated into an existing production line or can be operated individually, making them suitable for small-scale production as well. They can also be configured to produce various wafer products like chocolate-coated wafer sticks, wafer rolls, and wafer fingers.

In addition to flexibility, wafer stick machines also offer precise portion control, ensuring that each wafer stick is uniformly filled and sealed for consistency in taste and texture. These machines also come with advanced digital control systems, which allow for easy and accurate adjustments to the production process. This helps to minimize waste and maximize efficiency.

However, just like any other equipment, proper precautions must be taken while operating the wafer stick machine to ensure its smooth functioning and longevity.

Precautions for using a wafer stick machine:

1. Familiarize yourself with the machine

Before using the wafer stick machine, it is essential to read the instruction manual carefully and understand its functions. Familiarize yourself with the parts of the machine, their purpose, and how they work. This will help you operate the machine efficiently and reduce the risk of accidents.

2. Maintain a safe distance

It is crucial to maintain a safe distance from the moving parts of the wafer stick machine while it is in operation. This is especially important when loading the ingredients or removing the finished wafer sticks. Keep your hands and other body parts away from the conveyor belt and other moving parts to prevent injuries.

3. Use appropriate tools

When loading the ingredients into the machine, use the recommended tools provided by the manufacturer. Do not use your hands or any other sharp objects to push or position the ingredients. This can cause damage to the machine and increase the risk of injury.

4. Wear protective gear

While operating the wafer stick machine, it is important to wear appropriate protective gear, such as gloves and safety goggles. This will protect your hands from the hot surfaces and your eyes from flying debris.

5. Regular maintenance

To ensure the machine operates smoothly and efficiently, it is essential to perform regular maintenance. This includes cleaning and lubricating the moving parts, checking for any wear and tear, and replacing parts as needed. Consult the instruction manual for the recommended maintenance schedule and procedures.

6. Use the machine at the recommended temperature

The temperature of the machine is crucial in producing perfect wafer sticks. Make sure to operate the machine at the recommended temperature given in the instruction manual. Operating at a higher or lower temperature than recommended can result in burnt or undercooked wafer sticks.

7. Use the correct ingredients and measurements

To achieve the desired consistency and taste of wafer sticks, it is essential to use the correct ingredients and measure them accurately. This includes using the right type of flour, sugar, and other ingredients, as well as measuring them according to the recipe.

8. Do not overload the machine

Overloading the wafer stick machine can result in it malfunctioning or breaking down. Make sure to follow the recommended capacity for each batch and do not try to produce more than what the machine can handle.

How to clean a wafer stick machine:

1. Turn off the machine

Before cleaning the wafer stick machine, ensure that it is turned off and unplugged from the power source. This will prevent any accidents or malfunctions while cleaning.

2. Disassemble the machine

The first step in cleaning the machine is to disassemble it. Carefully remove the various parts and compartments, such as the hopper, conveyor belt, and baking plates.

3. Remove the leftover batter

Use a damp cloth or sponge to remove any excess batter or crumbs from the machine. Be gentle and avoid using sharp objects that can damage the machine.

4. Clean the parts with warm soapy water.

Using a mild dishwashing soap, clean the various parts of the machine with warm water. Be sure to remove any residue or debris from all the parts. You can also use a small brush or toothbrush to reach difficult areas.

5. Rinse and dry thoroughly

Rinse all the parts with clean water to remove any soap residue. Allow them to air dry completely before reassembling the machine. Make sure that all parts are completely dry before using the machine again.

6. Wipe the machine with a damp cloth

Using a damp cloth, wipe the exterior of the machine to remove any dust or spills. Avoid using harsh chemicals or abrasive materials, as they can cause damage to the machine’s surface.

7. Lubricate the moving parts

As part of the maintenance routine, it is important to lubricate the various moving parts of the wafer stick machine. Consult the instruction manual for the recommended lubricant and application methods.

8. Reassemble the machine

Once all the parts are dry, carefully reassemble the wafer stick machine. Ensure that all the parts are in the correct position and tightly secured.

SEMMCo Chocolate Machine Co., Ltd. is a professional food machinery enterprise located in Jiangsu, China. On the basis of continuous learning and innovation, our company has developed a large number of high-quality products and enjoys a good reputation among customers around the world. Our main markets are Chinese Mainland, Europe, North America and the Middle East.

Our main products include Chocolate Tools,Bakery Machines,Chocolate Tempering Machine,Chocolate coating Machine,Chocolate Cooling Tunnel,chocolate melter machine,chocolate moulding machine,chocolate processing machine,etc.Our company has a strong technical team. We keep pace with international advanced food machinery technology. In addition, we can also provide design and layout solutions for your factory.