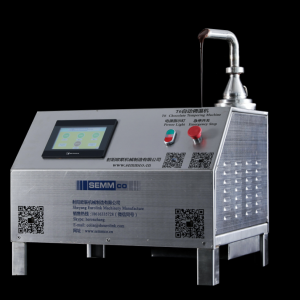

Description

Hand wheel device, capable of dumping and discharging

| Main technical parameters | |

| Loading capacity | 40kg |

| Equipment size | 116*80*129cm |

| Weight | 约280kg/about 280kg |

| Power supply | 380V-50HZ |

| Power | 3KW |

| Material | the shell is 304 stainless steel with built-in grinding roller made of natural rock |

| Speed | 0-80rpm, adjustable |

Tags: chocolate processing equipment

How to achieve precise temperature control in chocolate processing equipment to ensure the correct mixing, showering, shaping, and packaging process of chocolate?

Achieving precise temperature control in chocolate processing equipment is crucial to ensure the correct mixing, showering, shaping, and packaging of chocolate products.

Thermal Jackets and Heating Elements:

Equip processing equipment, such as mixing tanks, with thermal jackets or heating elements. These components allow for precise control of the temperature of the chocolate within the equipment.

Use electrical or steam-based heating systems to maintain consistent temperatures.

Thermostats and Temperature Probes:

Install thermostats and temperature probes within processing equipment to monitor and regulate chocolate temperature.

These sensors provide real-time data to ensure that the chocolate remains within the desired temperature range.

Double-Walled Tanks:

Use double-walled tanks for chocolate storage and tempering. These tanks provide an insulated environment that helps maintain consistent temperatures.

The space between the walls can be filled with temperature-controlled fluids (e.g., hot water) to regulate the chocolate’s temperature.

Continuous Agitation:

Equip processing equipment with continuous agitation systems such as stirrers or agitators. These systems help distribute heat evenly and prevent temperature variations within the equipment.

Air Conditioning and Insulation:

Install air conditioning systems in chocolate processing areas to control the ambient temperature. This is particularly important for chocolate tempering processes.

Ensure that equipment and storage areas are properly insulated to minimize temperature fluctuations caused by external factors.

Cooling Systems:

For cooling chocolate after processing, use cooling tunnels or cabinets with controlled air temperature and circulation to quickly solidify the chocolate at the desired temperature.

Temperature Monitoring and Control Systems:

Implement advanced temperature monitoring and control systems that offer precise digital control and feedback. These systems can automatically adjust heating or cooling as needed to maintain the set temperature.

Quality Control and Calibration:

Regularly calibrate and maintain the temperature control systems to ensure accuracy and reliability.

Implement quality control procedures to verify that the equipment is maintaining the correct temperature during production.