Description

MM60 Chocolate Enrober machine to coat chocolate for biscuit/cakes

1. Chocolate machine enrober is to coat chocolate on food such as biscuit , wafers , egg rolls cake pie and smacks etc.

2. Cooling tunnel is available and refrigeration effect is very good with 3 sets refrigeration unit.

3. Moreover,this production line can be customized as your personal requirement.

Technical Specification

Model: MM60

Capacity: 60kg

Power: 2kw

Voltage: Single phase, 220V

Dimension: 1220mm(L)x780mm(W)x1590mm(H)

MM60 standard moulding machine can be equipped enrobing belt, combined with enrobing machines. They are suitable for pralines and pastry products, from biscuit to cakes. The entire procedure can be carried out by just one operator, who can easily move from the loading and enrobing area to the product exit conveyor.

Chocolate Enrober available with Varsha Engineering Company is manufactured using cutting edge technology. Our company can supply Chocolate Enrober with electrical controller comprising independent units or cooling tunnel. Various attachments for sprinkling of items onto the enrobed chocolate can also be supplied on special request. The price of Chocolate Enrober offered by us is nominal as compared to other models offered by our competitors.

Tags: Chocolate Machine

What is the Function of a Chocolate Enrober Machine in the Confectionery Manufacturing Process?

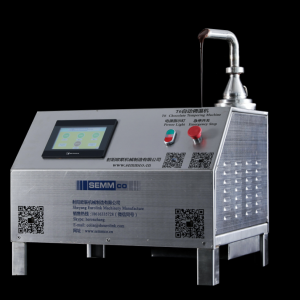

The function of SEMMCo chocolate enrober machine in the candy manufacturing process is to apply a smooth and uniform layer of chocolate on various candy products.

This automated device effectively wraps candies, cookies, nuts, or fruits through a layered curtain of tempered chocolate. It ensures accurate and consistent coating thickness, provides a smooth surface, and enhances the visual appeal of candy.

In addition, chocolate wrapping typically includes the functions of cooling and solidifying chocolate coatings, which help create delicious and professional finished products in the candy industry.

How Does a Chocolate Enrober Machine Ensure Even Coating of Chocolate on Confectionery Products?

SEMMco chocolate enrober machine ensures an even coating of chocolate on confectionery products through a carefully controlled and automated process. The key steps involved are:

Tempering: The chocolate is tempered to ensure proper crystalline structure, promoting a smooth and glossy finish.

Chocolate Curtain: The tempered chocolate is maintained in a liquid state and poured into a reservoir within the enrober.

Adjustable Flow: The flow of chocolate is meticulously regulated, allowing operators to adjust the thickness of the chocolate curtain.

Conveyor System: Confectionery items, such as candies or biscuits, are placed on a conveyor belt that passes through the chocolate curtain. The conveyor speed is synchronized with the chocolate flow to ensure an even coating.

Scraping and Return System: Excess chocolate is carefully scraped off the bottom of the coated products by a system of blades or rollers. The removed chocolate is returned to the chocolate reservoir for recycling, minimizing waste.

Vibration and Airflow: Some enrober machines incorporate vibration and airflow systems to further distribute the chocolate evenly and remove air bubbles, enhancing the smoothness and consistency of the coating.

Cooling Tunnel: Following the enrobing process, confectionery items pass through a cooling tunnel or chamber. Controlled cooling solidifies the chocolate coating, ensuring a glossy finish and preventing blooming (a white, dull appearance caused by improper crystallization).

By combining these precise control mechanisms, a chocolate enrober machine guarantees that each confectionery product receives an even, well-tempered chocolate coating, contributing to the visual appeal, taste, and quality of the final product.

What Features and Components are Essential in a High-Quality Chocolate Enrober Machine?

Key elements include a sturdy and hygienic design that meets industry standards, a precise temperature control system for chocolate tempering, and an adjustable flow mechanism for adjusting coating thickness.

The carefully designed conveying system ensures the smooth passage of the product through the chocolate curtain, while the scraping and return system minimizes waste by effectively removing excess chocolate.

In addition, high-quality intermediate fibers typically contain vibration and airflow systems to enhance the uniform distribution of chocolate and eliminate bubbles, ensuring a flawless coating.

A reliable cooling channel is crucial for curing chocolate coatings, obtaining a smooth surface, and preventing flowering.

How Does Temperature Control Play a Vital Role in the Performance of a Chocolate Enrober?

Temperature control plays an important role in the performance of the chocolate wrapping machine, affecting the quality of the chocolate coating and the overall efficiency of the wrapping machine process.

1. During the tempering process, precise temperature control is crucial, as chocolate is heated and then cooled to a specific temperature. Tempering ensures the formation of stable cocoa butter crystals, which contribute to the smooth texture, luster, and fracture of the chocolate coating.

2. Maintaining chocolate at the correct temperature ensures appropriate viscosity. If chocolate is too thick or too thin, it can cause uneven coating thickness and affect the appearance of the final product.

3. Controlling temperature is crucial for preventing flowering. Blooming is a phenomenon where chocolate appears white and dull due to improper crystallization.

4. In the cooling channel, precise temperature control is required to promote the correct solidification of the chocolate coating.

5. Temperature control can ensure consistency in different production operations. Maintaining a stable temperature throughout the entire coating process from tempering to cooling helps to maintain consistency in product quality.

6. Proper temperature control helps prevent issues such as chocolate clumping, uneven coating, or excessive dripping, thereby minimizing waste.

7. Temperature control is crucial for ensuring that chocolate remains within a safe temperature range and preventing the growth of harmful bacteria.

What Types of Confectionery Products are Typically Processed Using Chocolate Enrober Machines?

The chocolate enrober machine is a multifunctional device used to wrap various candy products.

Common candies include chocolate, truffles, fructose, and candies. Biscuits and wafer products can also be wrapped to add a delicious chocolate layer.

In addition, items such as cotton candy, toffee, and caramel can be wrapped together to form a smooth and indulgent outer layer.