Description

1.Equipment configuration list

| NO | Device name | Unit | Quan tity | Configuration | ||||

| Electric fittings | Transmissi on parts | Appearance material | Mode of operation | Navar | ||||

| 1 | Bake box | Short for Taizho u | 1 | Denver frequency converter Siemens operation, navar | SKF bearing | Contact surface 304 | touch screen Show the operation | Motor start PLC touch screen control frequency control |

| 2 | forming machine | Short for Taizho u | 1 | Denver frequency converter Siemens motor drive | SKF bearing | A3 plate plating | push-butt on | Motor start frequency control |

| 3 | Electric control cabinet | short for Taizho u | 1 | Denver frequency converter Siemens operation, navar | SKF bearing | Contact surface 304 | touch screen Show the operation | Motor start frequency control |

| 4 | Injectio n core pump group | group | 1 | Denver frequency converter Siemens motor drive | SKF bearing | Contact surface 304 | push-butt on | Motor start frequency control |

| 5 | Surface paddle pump group | group | 1 | Denver frequency converter Siemens motor drive | SKF bearing | Contact surface 304 | push-butt on | Motor start frequency control |

| 6 | agitator | short for Taizho u | 1 | Denver frequency converter motor drive | SKF bearing | Contact surface 304 | push-butt on | Motor start frequency control |

| 7 | storage vat | short for Taizho u | 1 | SKF bearing | Contact surface 304 | push-butt on | Motor start frequency control | |

| 8 | Packagin g conveyor belt | short for Taizho u | 1 | Denver frequency converter Siemens operation, navar | SKF bearing TR with seat | Contact surface 304 PU belt delivery | touch screen Show the operation | Motor start PLC touch screen control control |

2.Equipment technical parameters table

| order number | project | specifications |

| 1. | Load requirements | 3000KG/m² |

| 2. | Host size | 3000mm×1870mm×2850mm |

| 3. | Host weight | 6500KG |

| 4. | Size of the slurry supply machine | Core pump set: 1470mm 1100mm 1500mm Face paddle pump set: 1580mm 1140mm 1100mm |

| 5. | Weight of the slurry supply machine | Core injection pump set: 400kg Face paddle pump set: 300kg |

| 6. | Conveyor size | 3710mm×1180mm×1450mm |

| 7. | The weight of the conveyor | 100kg |

| 8. | output | The product output depends on the product specification. Based on the conventional internal diameter of φ 8mm 70mm length product (including injection core), the production capacity is about 480 pieces / minute, and the output per hour is about 28800 pieces. If the weight of each root is about 7g, that is, the yield is about 200kg per hour. |

| 9. | plant capacity | 30Kw |

| 10. | Gas type | LPG / Natural Gas |

| 11. | gas consumption | LPG: about 8kg / h Natural gas: about 16m³/ h |

| 12. | Quantity of slurry forming | Four |

| 13. | Bottom temperature heating method | Direct open fire combustion |

| 14. | Combustion mode of surface temperature | Japanese infrared burner |

| 15. | Temperature control mode | PLC control |

| 16. | Ignition mode | PLC control |

| 17. | Burn monitoring mode | PLC control |

| 18. | Flame extinguishing safety protection mode | PLC control |

| 19. | Cut off the way | Servo spin cut |

| 20. | Length detection method | photoelectric switch |

| 21. | Main slurry delivery mode and control | Frequency conversion potentiator |

| 22. | Delivery mode and control of side slurry | Screw pump frequency conversion speed control |

| 23. | Core injection material delivery mode and control | Screw pump frequency conversion speed control |

| 24. | Large roller speed adjustment | PLC touch screen control |

| 25. | Forming speed adjustment | PLC touch screen control |

| 26. | Pulp speed adjustment | PLC touch screen control |

| 27. | Conveyor speed adjustment | PLC touch screen control |

| 28. | The bucket heating | Electric heating joins the PLC touch screen control |

| 29. | Mix the bucket | PLC touch screen control |

| 30. | Bucket material | 304 Laminated stainless steel |

| 31. | Large roller speed reducer brand | China |

| 32. | Forder bearing brand | Sweden SKF |

| 33. | Forming motor brand | siemens |

| 34. | Frequency converter brand | Denvers |

| 35. | PLC brand | siemens |

| 36. | photoelectric switch | OMRON |

| 37. | Ignition solenoid valve | China |

| 38. | Ignition controller | China / USA |

| 39. | Control electrical | Schneider of France |

| 40. | Console cover | 304 Stainless steel |

| 41. | Conveyor outer cover | Aluminum alloy + 304 stainless steel |

3.Actual shot pictures of the equipment

| set up have complete view graph

|  |

| wrap dress transport deliver belt

|  |

|

|  |

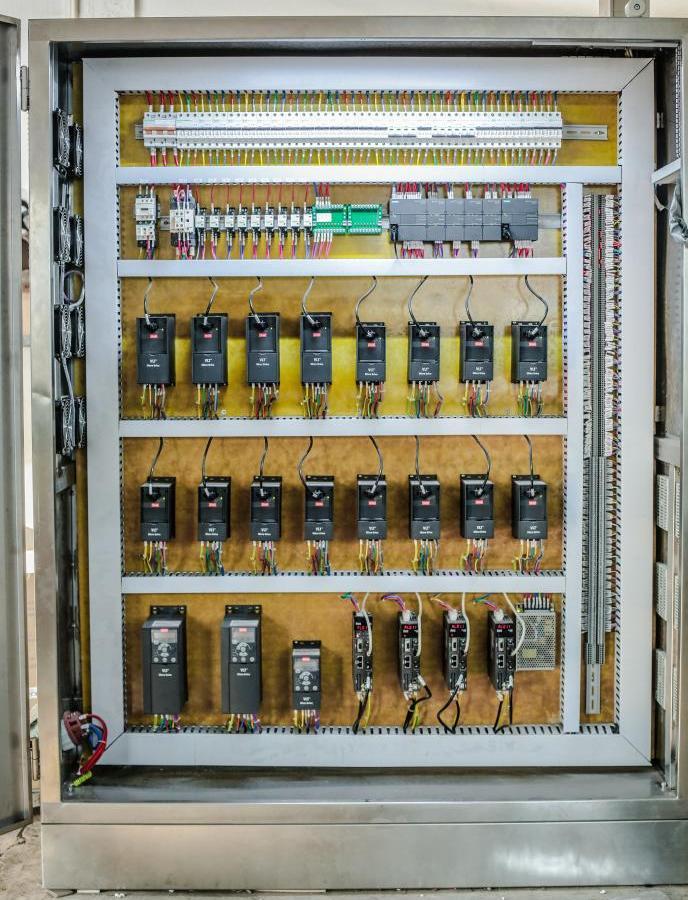

| Interior view of the main electric | Component diagram of molding machine control cabinet |

|

|

| Appearance diagram of the injection core pump set | Appearance drawing of the surface slurry pump set |

Chocolate Enrobe+Cooling Tunnel(280mm 宽)

Introduction:

▶ The whole chocolate coating line can be classified into two parts:

dip-coating and cooling tunnel. Dip-coating machine adopts automatic temperature control for heating, slurry transmission from slurry barrel,

cooling tunnel which assembles special circle ventilation; it is more applied to process flow for chocolate manufacturing, adjusting with classification.

This machine characterizes as huge cooling value, high yield, which applies to all kinds of novelty products.

▶ It features by particular and compact structure design ,advanced and perfect system configuration, stable running, easy operation, safety and reliability, simple repair and maintenance.

Chocolate Enrobe:

-Wire mesh Width: 280mm.

– Made of SUS304 stainless steel.

-All surface coating, bottom coating, and up-side coating

Cooling Tunnel:

Width of conveyor belt: 280mm,

Details:

1) Will be matched to the ENROBER, made of SUS304 stainless steel. The covers can be opened by gas spring from one side. The insulation cover is made of 30mm stainless steel sandwich plate

2) Speed of conveyor belt: 0.5-6.5M/min

3) There is temperature sensor; temperature can be controlled by temperature controller.

4) There are pneumatic rectifying belt devices in front and back rack.

5) 1 sets of 3Hp cooling unit

SELL TERMS

1.Terms of Payment

The Payment by Installment Should Be Paid In Time. Each Installment Should Be As Per The Under-Mentioned Terms Of Payment, Otherwise The Shipment Date Will Be Postponed

Accordingly.

The First Payment(50% Of Total Price) As Deposit Should Be Paid To Seller Within Seven(7) Working Days After Signed The Contract.

The Balance (50% of Total Price) Should Be Paid By T/T to Seller by Buyer within Five Working Days before Shipment All Bank Charges Outside China Are For Account Of Buyer.

The Exchange Rate According To Date of Sign the Contract.

2.Guarantee

Party B (Seller) Has Agreed To Provide 12 Months Guarantee Period From The Date Of Installation But Not More Than 15 Month From The Date Of Shipment. Against Any Manufacturing Defects And Faulty Materials. During This Guarantee Period Any Items Or Parts Found To Be

Defective, Will Be Replaced By Party B (Seller) To Party A (Buyer) Free Of Charge. Ware And Tare Parts And Parts Damaged By Any External Cause Shall Not Be Covered Under This Guarantee.

3.Supervision of Installation and Commissioning Of the Plant Party B (Seller) Has Agreed to Send 2-5 Technical Personnel to Carry out Work of the Installation, Commissioning Of The Plant And Training Of The Operator With Regard To Production And Maintenance Of The Plant. Party A (Buyer) Has To Bear The Cost Of Round trip Tickets, Food and Lodging For Two Persons For A Period Of 25 Days. In Addition, A Daily Allowance Of USD 50 Per Technician As Pocket Money During Their Stay In Buyers Country.

4.The appearance of the equipment is constantly upgrading. The above pictures are for reference only.

5.Offer validity: 30 days Delivery date: 45 days